I. Design and Selection Considerations

- Temperature Range Compatibility

- Ensure the NTC's operating temperature range covers the AC system’s environment (e.g., -20°C to 80°C) to avoid performance drift or damage from exceeding limits.

- Accuracy and Resolution

- Select high-precision sensors (e.g., ±0.5°C or better) to enhance temperature control sensitivity. Resolution should match the system’s requirements (e.g., 0.1°C).

- Response Time Optimization

- Prioritize sensors with low thermal time constants (e.g., τ ≤10 seconds) to enable rapid feedback and prevent compressor cycling.

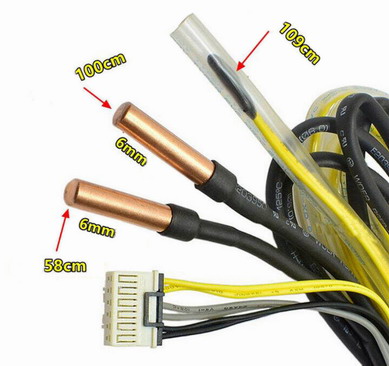

- Packaging and Durability

- Use epoxy resin or glass encapsulation to resist humidity, condensation, and chemical corrosion. Outdoor unit sensors should meet IP67 rating.

II. Installation Position and Mechanical Design

- Location Selection

- Evaporator/Condenser Monitoring: Attach directly to coil surfaces, avoiding direct airflow (e.g., >5 cm from vents).

- Return Air Temperature: Install at the center of return ducts, away from heating/cooling sources.

- Thermal Coupling

- Secure sensors with thermal grease or metal clamps to minimize thermal resistance between the sensor and target surface.

- Airflow Interference Mitigation

- Add airflow shields or use probes with shielding to reduce wind speed effects (critical for air-cooled systems).

III. Circuit Design Guidelines

- Voltage Divider Parameters

- Match pull-up resistors to the NTC’s nominal resistance (e.g., 10kΩ at 25°C) to ensure ADC input voltage falls within the effective range (e.g., 1V–3V).

- Linearization

- Apply the Steinhart-Hart equation or piecewise lookup tables to compensate for nonlinearity and improve accuracy.

- Noise Immunity

- Use twisted-pair/shielded cables, route away from high-noise sources (e.g., compressors), and add RC low-pass filters (e.g., 10kΩ + 0.1μF).

IV. Environmental Adaptability

- Moisture Protection

- Seal outdoor sensors with potting compounds and use waterproof connectors (e.g., M12 aviation plugs).

- Vibration Resistance

- Secure sensors with flexible mounts (e.g., silicone pads) to prevent contact issues from compressor vibrations.

- Dust Prevention

- Regularly clean sensors or use removable protective covers (e.g., metal mesh).

V. Calibration and Maintenance

- Multi-Point Calibration

- Calibrate at key temperatures (e.g., 0°C ice-water mixture, 25°C thermal chamber, 50°C oil bath) to address batch variations.

- Long-Term Stability Checks

- Perform field calibration every 2 years to verify drift (e.g., annual drift ≤0.1°C).

- Fault Diagnostics

- Implement open/short-circuit detection and trigger alerts (e.g., E1 error code) for abnormalities.

VI. Safety and Compliance

- Certifications

- Ensure compliance with UL, CE, and RoHS standards for safety and environmental requirements.

- Insulation Testing

- Verify cable insulation withstands 1500V AC for 1 minute to prevent breakdown risks.

Common Issues and Solutions

- Issue: Delayed sensor response causing compressor cycling.

Solution: Use smaller probes (lower τ) or optimize PID control algorithms. - Issue: Condensation-induced contact failure.

Solution: Reposition sensors away from condensation zones or apply hydrophobic coatings.

By addressing these factors, NTC sensors can ensure reliable operation in AC systems, improving energy efficiency (EER) and extending equipment lifespan.

Post time: Apr-25-2025