Fiberglass Wire Flanged Temperature Sensor for Air Fryer,Microwave oven,Electric oven

Single Side Flange Air Fryer Temperature Sensor

This is a common temperature sensor in kitchen appliances, which uses high thermal conductive paste injected into the tube to speed up the heat conduction, flange fixing process for a better fixation and food-level SS304 tube for a better food safety. Glass fiber wire is generally used for high temperature resistant products. It can be designed and produced according to every single requirement such as size, outline, characteristics and so on. The customization can help customer have an easy installation, especially the products with flange.

Features:

■ Glass-encapsulated thermistor elements which withstand high voltage are available

■ Outstanding accuracy and response solution for oven temperature control

■ Max. temperature up to 300℃ (from the tip of protection tube to the flange)

■ Usage of Food-grade level SS304 housing, meet the FDA and LFGB certification.

■ Products are in accordance with the RoHS, REACH certification.

Applications:

■ Air Fryer, Baked Oven, Electric oven

■ Microwave oven chambers (air & vapor)

■ Heaters and Air Cleaners (inside ambient)

■ Water dispenser

■ Vacuum cleaners (solid)

Characteristics:

1. Recommendation as follows:

R25℃=100KΩ±1% B25/50℃=3950K±1% or

R25℃=98.63KΩ±1% B25/85℃=4066K±1% or

R200℃=1KΩ±3% B100/200℃=4300K±2%

2. Working temperature range: -30℃~+200℃ or -30℃~+250℃ or -30℃~+300℃

3. Thermal time constant: MAX.7sec.( typical in stirred water )

4. Insulation voltage: 1800VAC,2sec.

5. Insulation resistance: 500VDC ≥100MΩ

6. Glass fiber wire or Teflon cable UL 1332 or XLPE cable is recommended

7. Connectors are recommended for PH, XH, SM, 5264 and so on

8. Above characteristics all can be customized

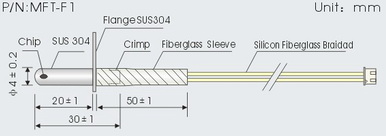

Dimensions:

Product Specification:

|

Specification

|

R25℃

(KΩ) |

B25/50℃

(K) |

Disspation Constant

(mW/℃) |

Time Constant

(S) |

Operation Temperature

(℃) |

| XXMFT-10-102□ | 1 | 3200 |

2.1 - 2.5 typical in still air at 25℃

|

60 - 100

typical in still air MAX.7 sec. typical in stirred water |

-30~200

-30~250

-30~300

|

|

XXMFT-338/350-202□

|

2

|

3380/3500 | |||

| XXMFT-327/338-502□ | 5 | 3270/3380/3470 | |||

|

XXMFT-327/338-103□

|

10

|

3270/3380 | |||

| XXMFT-347/395-103□ | 10 | 3470/3950 | |||

|

XXMFT-395-203□

|

20

|

3950 | |||

| XXMFT-395/399-473□ | 47 | 3950/3990 | |||

|

XXMFT-395/399/400-503□

|

50

|

3950/3990/4000 | |||

| XXMFT-395/405/420-104□ | 100 | 3950/4050/4200 | |||

| XXMFT-420/425-204□ | 200 | 4200/4250 | |||

|

XXMFT-425/428-474□

|

470

|

4250/4280 | |||

| XXMFT-440-504□ | 500 | 4400 | |||

| XXMFT-445/453-145□ | 1400 | 4450/4530 |